Product Description:

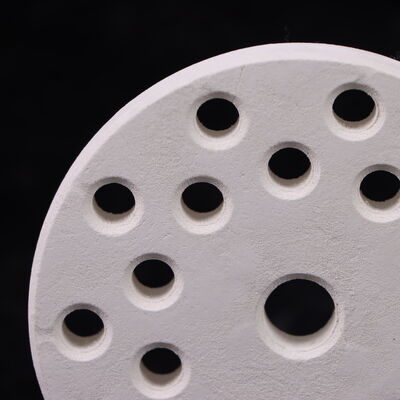

The High Temperature Mullite Ceramic is an advanced engineered mullite ceramic material designed to perform exceptionally well in demanding environments. Composed primarily of 3Al2O3·2SiO2, this unique chemical composition grants the material outstanding thermal and mechanical properties, making it an ideal choice for applications requiring durability and stability at elevated temperatures.

Mullite ceramic, known for its excellent thermal shock resistance and low thermal expansion, is widely utilized in industries that operate under high temperature conditions. The engineered mullite ceramic material exhibits a melting point ranging between 1840 to 1850 °C, which ensures its stability and integrity even in the harshest thermal environments. This high melting point allows it to maintain structural strength and resist deformation, making it indispensable in furnace linings, kiln furniture, and heat exchangers.

One of the key attributes of this high temperature mullite ceramic is its impressive mechanical strength, which typically ranges from 200 to 300 MPa. This mechanical robustness enables the material to withstand significant mechanical stresses and loads without cracking or failing. As a result, it is frequently employed in applications where both thermal resistance and mechanical durability are critical, such as in refractory components and high-performance insulation systems.

Porosity is an important factor that influences the performance of ceramic materials. The engineered mullite ceramic material features a porosity typically below 15%, which contributes to its excellent mechanical strength and thermal conductivity. Low porosity enhances the material’s resistance to wear, corrosion, and chemical attack, further extending its lifespan in aggressive industrial environments. This characteristic also improves the material’s ability to act as an effective thermal barrier, minimizing heat loss and improving energy efficiency in high temperature processes.

The combination of chemical composition, mechanical strength, melting point, and low porosity makes this high temperature mullite ceramic a versatile and reliable solution for a wide range of industrial applications. It is particularly valued in sectors such as metallurgy, glass manufacturing, petrochemical processing, and aerospace engineering, where materials are routinely exposed to extreme heat and mechanical stress.

In addition to its excellent thermal and mechanical properties, the engineered mullite ceramic material is also known for its outstanding chemical stability. It resists oxidation and corrosion even at elevated temperatures, ensuring long-term performance without degradation. This chemical inertness makes it suitable for use in environments where exposure to molten metals, slags, and aggressive chemicals is common.

Furthermore, the high temperature mullite ceramic’s ability to maintain dimensional stability under rapid temperature changes helps prevent thermal shock failure, a common issue in many refractory materials. This enhances operational safety and reduces maintenance costs by minimizing downtime and the need for frequent replacements.

In summary, the high temperature mullite ceramic is an exceptional engineered mullite ceramic material characterized by its chemical composition of 3Al2O3·2SiO2, high mechanical strength of 200 to 300 MPa, a melting point between 1840 and 1850 °C, and low porosity typically under 15%. These attributes collectively ensure superior performance in high temperature applications, making it an ideal choice for industries requiring durable, heat-resistant, and chemically stable ceramic components.

Features:

- Product Name: High Temperature Mullite Ceramic

- Thermal Expansion Coefficient: 4.5 - 5.5 × 10⁻⁶ /K

- Thermal Shock Resistance: 250

- Working Temperature: Up to 1400℃

- Color: White To Light Brown

- Applications: Refractory Linings, Kiln Furniture, Electrical Insulators

- Advanced Mullite Ceramic Material designed for high durability and performance

- Engineered Mullite Ceramic Material ideal for high temperature and thermal shock environments

Technical Parameters:

| Material |

Mullite Ceramic |

| Origin |

China |

| Color |

White To Light Brown |

| Thermal Conductivity |

3.5 - 4.5 W/m·K |

| Thermal Expansion Coefficient |

4.5 - 5.5 × 10⁻⁶ /K |

| Thermal Shock Resistance |

250 |

| Dielectric Constant |

6 - 7 |

| Mechanical Strength |

200 - 300 MPa |

| Hardness |

7 - 8 Mohs |

| Applications |

Refractory Linings, Kiln Furniture, Electrical Insulators |

Applications:

The KAMTAI High Temperature Mullite Ceramic product, model number MOLAISHITAOCI, is expertly crafted in China and certified under ISO 9001, ensuring top quality and reliability. Designed to withstand extreme conditions, this mullite ceramic material boasts exceptional mechanical strength ranging from 200 to 300 MPa and can operate continuously at temperatures up to 1400℃. With a melting point between 1840 and 1850℃ and a density of 3.1 to 3.2 G/cm³, it is an ideal solution for demanding industrial applications.

This High Temperature Mullite Ceramic is widely used in refractory linings where durability and thermal resistance are critical. Its outstanding thermal stability makes it perfect for lining kilns, furnaces, and other high-temperature environments, protecting structural components from thermal shock and chemical corrosion. The product’s capability to maintain integrity at elevated temperatures ensures longevity and optimal performance in harsh industrial conditions.

Additionally, the KAMTAI mullite ceramic serves as essential kiln furniture, providing sturdy support for ceramic wares during firing processes. Its excellent thermal insulation properties help to maintain consistent temperatures and improve energy efficiency within kilns. This Mullite Ceramic Thermal Insulator is particularly valued in ceramics manufacturing, metallurgy, and glass industries where precise temperature control is paramount.

Furthermore, the product is suitable for use as electrical insulators due to its low thermal conductivity and high mechanical strength, making it reliable in high-voltage and high-temperature electrical applications. Its resistance to wear and thermal degradation ensures stable performance under continuous operational stress.

KAMTAI offers this high-performance mullite ceramic with a minimum order quantity of 1000PCS, packaged securely in wooden boxes to prevent damage during shipment. With a supply capacity of 500,000 pieces per month and a delivery time of 30 days after payment, customers can rely on prompt and consistent availability. Payment terms are TT, and pricing is negotiable to accommodate various business needs.

In summary, the KAMTAI High Temperature Mullite Ceramic is a versatile and robust material tailored for use in refractory linings, kiln furniture, and electrical insulators, providing superior thermal insulation and mechanical strength for high-temperature industrial applications.

Customization:

At KAMTAI, we offer comprehensive product customization services for our Mullite Ceramic Thermal Insulator, model number MOLAISHITAOCI. Our advanced Mullite Ceramic Material is designed and manufactured to meet your specific requirements, ensuring optimal performance in various applications such as refractory linings, kiln furniture, and electrical insulators.

Originating from CHINA and certified with ISO 9001, our advanced Mullite Ceramic Material boasts excellent properties including a thermal expansion coefficient of 4.5 - 5.5 × 10⁻⁶ /K, chemical composition of 3Al2O3·2SiO2, density ranging from 3.1 to 3.2 G/cm³, and thermal conductivity between 3.5 - 4.5 W/m·K.

We accommodate minimum order quantities starting from 1000PCS, with a supply ability of up to 500000PCS per month. Pricing is negotiable to best suit your business needs. All products are carefully packaged in sturdy wooden boxes to ensure safe delivery within 30 days after payment. Our payment terms are TT, providing flexibility and security for your transactions.

Choose KAMTAI for your Mullite Ceramic Thermal Insulator needs and benefit from our advanced Mullite Ceramic Material, tailored to deliver superior thermal insulation and durability for your industrial applications.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!